Replacing SecureIt Weapon Racks

Combat Weapon Storage was awarded a contract to replace a SecureIt weapon rack system that was sold and installed with less than 18″ of clearance to fire sprinklers, a violation of fire code. This same system also had a poor installation with an out of level track that was not grouted, cabinets not fully anchored to the carriages and only 1 access aisle for 1,000 weapons. The vendor even had the nerve to write up a fake case study on their Web site that they market extensively.

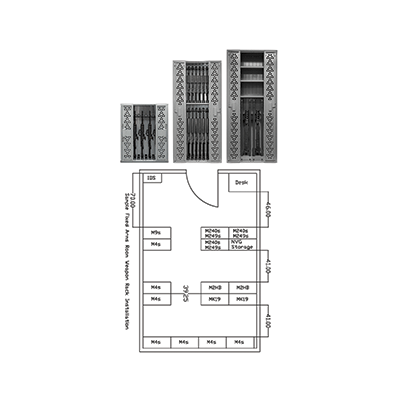

This SecureIt weapon rack system installed in an Air Force armory on mobile carriages had design and performance issues in addition to the installation issues. This included one access aisle for armorers with bi-fold door weapon racks.

Bi-fold weapon rack doors fold in half and stick out in front of the weapon racks, obstructing aisles approximately 9.5″. When facing weapon racks both have their doors open, 19″ of aisle space is lost, forcing armorers to constantly open and close doors. In this case there was only a 42″ W aisle with 19″ of that being obstructed by bi-fold weapon rack doors leaving 23″ of access, below the UBC code for egress. Mobile carriages cannot be moved with bi-fold weapon rack doors open or the doors will be damaged.

The constant opening and closing of bi-fold weapon rack doors with only one access aisle was an instant negative for the armory to maneuver between carriages within the system, severely restricting workflow and the ability to issue weapons effectively. The unit was written up for the 18″ fire code violation and ultimately had no choice to replace the system.

Another issue with the material handling weapon racks is the use of plastic bins, which are extremely restrictive when compared to full width adjustable storage shelves. Plastic bins have fixed widths and depths and effectively reduce storage capacity inside of weapon racks.

Bi-fold weapon rack doors obstruct aisle access and reduce aisle space by 9.5″. This effectively forces armorers to constantly open and close the doors to access aisles, issue weapons and navigate through a tight space when carrying weapons in and out of the system.

With the aisle collapsed, 19″ of aisle space is lost with facing cabinets. In a single aisle high density system such as this, that left 23″ of usable aisle space. 23″ of aisle is a less than legal aisle and not enough space for access to weapon racks with the bi-fold doors opening out 9.5″. The bi-fold doors can’t be left open while operating a high density carriage system.

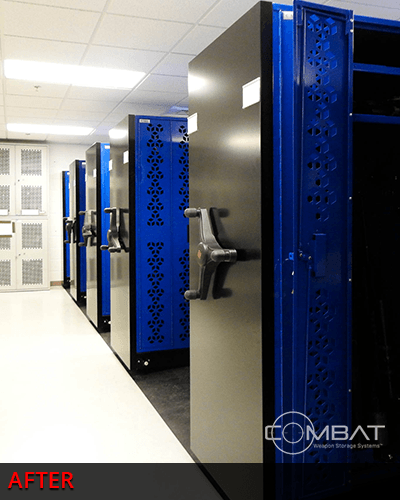

For this project we utilized a custom height Combat Weapon Rack to ensure we stayed 18″ under the fire sprinklers with the racks installed on top of mobile carriages. Featuring reverse bi-fold doors, carriages can now be moved without opening and closing each weapon rack door.

Storage shelving was also supplied on multiple mobile carriages for weapon case and gear storage as well as ammo storage with secure doors.

Wall to wall track was installed leveled, anchored and fully grouted allowing the armorers to have multiple access aisles between carriages, increasing the armory workflow with the option to add additional weapon racks or shelving on carriages at a minimal add-on cost in the future.

Flooring inside of the carriage system was finished with rubber matting to protect weapons from damage if they are dropped and a painted non-skid ADA steel access ramp. Full height, solid steel end panels finish off the system with a push button safety lock for each mobile carriage on the handle.

The mobile carriage system installation started with a tear down, removal, relocation and installation of the SecureIt Weapon Rack system. The system is being retrofitted with storage shelves to be used for supply storage.

As a licensed contractor in the State of California #701914, it is imperative that vendors understand and implement basic understanding of local state and building codes into the design element of weapon rack systems and installations.

Here you can clearly see the flange of the track being bowed by an anchor, leaving the track out of level and the anchor not flush, which allows for track flex. The vendor left the concrete dust behind from drilling the concrete for anchors. Vibration causes leveling feet track systems to go out of level over time.

Anti-tip track installed level to the high spot of the floor with leveling screws, anchored and fully grouted before the leveling screws are removed. Grout under the rail ensures the track stays level.

The single aisle system was too restrictive and was replaced with wall to wall track that gave the armory multiple access aisles and additional shelving for items that were previously stored on the floor.

Multiple access aisles allow for more than one armorer to access the system at a time, increasing the workflow of the armory. Shelves provide additional storage within the mobile storage system getting all equipment on shelves and off the floor.

Combat Weapon Racks on high density mobile carriages speeds up armorers with reverse bi-fold doors, secures weapons, meets building codes and is installed by a licensed contractor.

Contact Us Now For More Information.