High Density Weapon Storage Safety Features

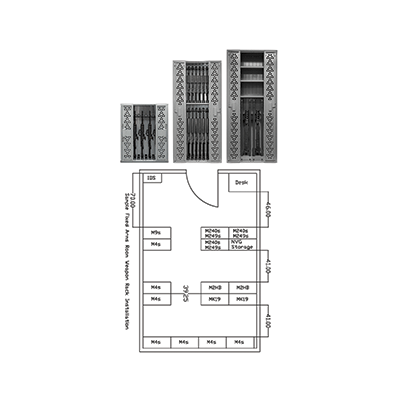

- Determine the amount of space available inside the arms room with an Armory Site Survey

- Review the weapon density list against Weapon Rack Storage Capacity

- How many weapon racks do I need?

- Contact us for GSA Weapon Rack Pricing or review NSN Weapon Racks for supply system purchases

- Ask about how to utilize DLA TLS (Tailored Logistics Support) contract

We detailed how High Density Weapon Storage Systems are configured in a previous post: See High Density Weapon Storage blog post for more details

This post is explicitly for High Density Weapon Storage Safety Features.

Mobile carriage systems are available as manual, mechanical assist (hand crank) or electric carriage systems.

- Manual systems have a fixed handle and are dragged from side to side. These types of systems should not be used in armories.

- Mechanical Assist (hand crank) mobile carriage systems are the most common type of system as they have no cost of ownership and are predominantly maintenance free.

- Electric mobile carriage systems are typically only used in larger projects that need advanced safety features or for PIN code access for specific access aisles. These systems require maintenance contracts to have the electronic components serviced and operational.

How Do Mobile Carriage Systems Work?

Mechanical assist handles rotate to drive carriages. Multiple carriages can be moved effortlessly with one handle. Here is a technical description of how carriages work.

Handles are attached to a chain in an enclosed and concealed gear box that chains over to the full length, torque resistant tubular drive shaft, driving mobile carriages at every wheel channel. The all rail direct drive system includes a full length drive shaft 5″ wheel at every rail location. This creates uniformly distributed pulling forces. Large diameter torque resistant drive shafts provide power to all wheels connected to the line shaft, with mobile carriages rolling smoothly. (As easy as a 10-speed bicycle chain)

Full length drive shafts coupled with all dual flanged wheels prevent fishtailing with imbalanced loads & reduces stress on the carriage structure, extending the life of systems.

All 5″ diameter hardened steel wheels provide larger turning diameter, minimizing the number of handle rotations required to access each aisle and lowers the wear on the handle.

High Density Weapon Storage Safety Features

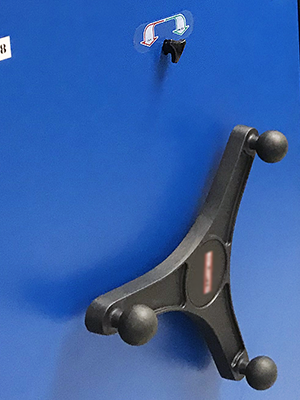

Combat Weapon Storage Systems has partnered with Montel to provide mobile carriage systems. Utilizing SafeCrank ergonomic 3 spoke handles, simply pressing the aisle safety button located in the center of the handle on adjoining carriages to secure an access aisle. A locked handle prevents the engaged mobile carriage from moving. To unlock the carriage, simple press the aisle safety button again and the lock is disengaged.

Other systems have lock knobs that require twisting, pinching and turning or plunger style push pin lock rods that have to line up perfectly for the lock rod to engage inside the handle. These safety mechanisms work, however they require extra work to secure the working aisle and are not ideal.

Working with armorers for many years the carriage locks that require twisting, pinching and turning just do not get utilized. A secondary high density weapon storage safety feature is the mechanical safety brake. This is a shock-absorber coupling in the toe-level bar at the base of the carriage. When the toe-level bar is engaged, the carriage will automatically stop. Only light pressure is needed for the bar to activate the brake mechanism.

This second layer of safety ensures that armorers are fully safe within a carriage system with weapon racks that can be up to or over 7 feet in height, obstructing views from adjacent aisles. Active arms rooms with multiple aisles being accessed at a time should demand a mechanical safety brake in each aisle for their system.

The Aisle Safety Push-Button, a safety device on our mobile mechanically assisted systems, makes locking & unlocking SafeCrank handles easy, thanks to its circular button which, when activated, prevents the movement of the system.

Competitor system with a lock knob that requires twisting, pinching & turning & have to line up perfectly for the lock rod to engage inside the handle. These safety mechanisms work, however they require extra work to secure the working aisle & are not ideal.

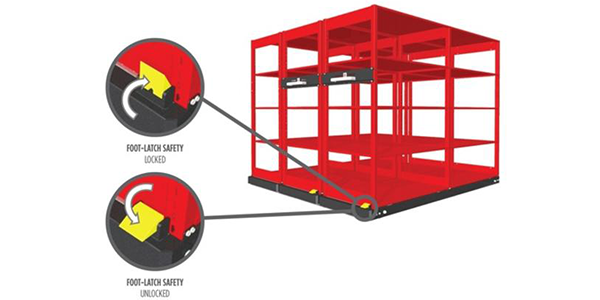

The mechanical safety brake on our mechanical-assist mobile storage systems ensures complete protection for users and objects.

Our foot-latch safety for manual mobile storage systems is the ideal option to prevent the mobile storage system from moving. Engaging the foot-latch safety before entering an aisle prevents other users from operating a system already in use.