How to Build an Armory

- Determine the amount of space available inside the arms room with an Armory Site Survey.

- Review the weapon density list against Weapon Rack Storage Capacity.

- How many weapon racks do I need?

- Contact us for GSA weapon rack pricing or review NSN Weapon Racks for supply system purchases.

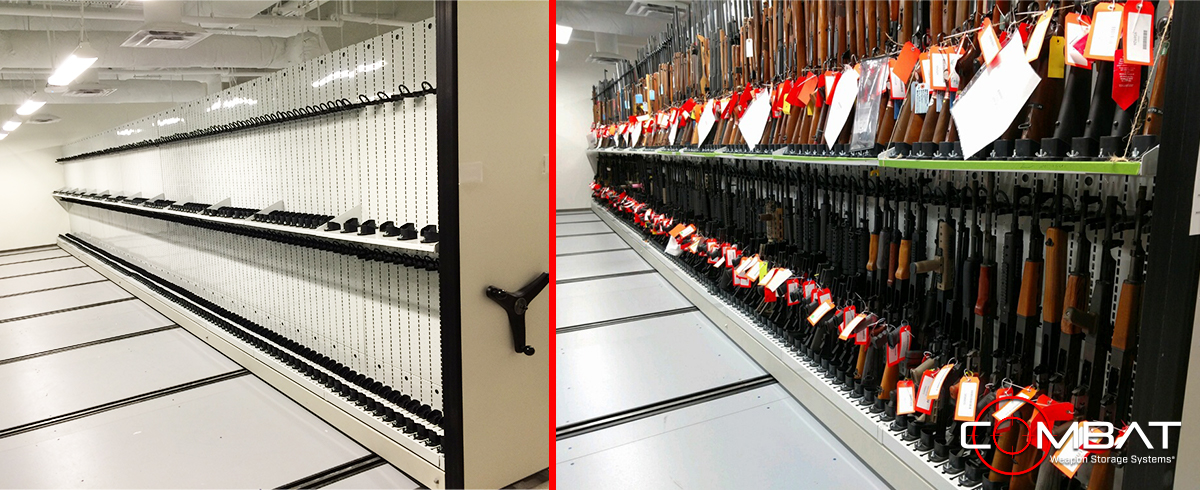

High Capacity Armory Storage Systems are designed to eliminate fixed aisles between static rows of weapon racks or shelving and increase storage capacity. In large arms vaults, there are times when the floor space is great enough to store all weapons without requiring a Mobile Weapon Storage System.

When the total amount of weapon storage exceeds the open available usable floor space, the answer quickly becomes mobile carriages. Moveable carriages conceptually create floating ranges of storage or aisles. Weapon Racks or Weapon Shelving mounted to moveable carriages will roll from side to side creating working aisles for armorers to enter and access the storage system.

Things to consider for high capacity armory storage system implementation.

- Workflow in the Armory

- Installation of the System

- Anti-Tip Track

- Floor Covering

- Safety Features

- 18″ Fire Sprinkler Clearance

- Reverse Bi-Fold Doors

Armory Workflow

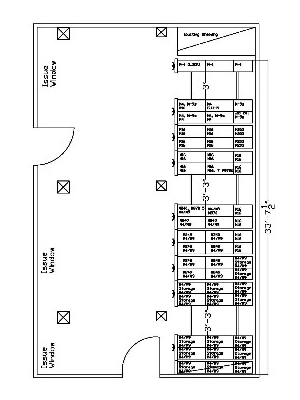

Designing a high capacity armory storage system begins with a site survey to assess the available space. Measuring the arms room, we capture the H x W X D including IDS locations, issue windows, pipes, vents, power outlets, HVAC, fire alarms, fire sprinklers, etc.

Once the usable space is defined, the armory is drawn in AutoCAD. Reviewing the MTOE or weapon density list, we are able to determine exactly how many weapon racks are needed to store the weapons and gear. The system designer is then able to define the necessary quantities of weapon storage.

In active armories, high capacity armory storage systems need to account for how many armorers may need access to the system at the same time. With every armory being a unique space, this means that some armories will require multiple access aisles for armorers to access weapons.

Installation of High Capacity Armory Storage Systems

The installation of the track is the most important part of the installation process. If the track is installed out of level or ever becomes out of level, the carriages will have performance issues that will cause failure and maintenance costs over time.

The track should be installed level, to the high spot of your concrete slab, anchored and fully grouted continuously under the entire span of each piece of track. Grout packed under the track keeps the track from ever coming out of level. Systems using only leveling feet should be avoided as leveling feet can shift and become out of level easily, causing major system issues.

Anti-Tip Track

The system should also be sold with anti-tip track. Anti-tip track protects the system from any seismic events or from a carriage from ever flipping over. Anti-tip track has a channel along the entire length of the track with a gripper plate installed under the carriage riding in the channel.

Unlevel tracks causes the anti-tip bracket to hit the track in high &/or low spots causing friction or resistance that eventually wears down carriage gears and chains. We replaced a system with an out of level track recently that caused major performance issues for the armory, because it was not grouted.

Floor Covering

Once the track is leveled, anchored and fully grouted, wood decking is installed between the rails and finished with floor covering, typically rubber matting to protect the floor and weapons if they are dropped.

The track and flooring is then completed with a non-skid ADA compliant steel ramp.

Tracks can also be installed embedded in concrete. The option to embed track in concrete is typical in new construction and eliminates having to install decking, flooring between tracks and an entry ramp.

Mobile Storage System Safety Features

Mobile Storage systems are available with standard carriage or aisle locks that are active locks, typically a knob or button that locks the handles in front of an aisle that protects the end user from the carriages closing on them when they are inside of the system.

In an armory, these safety mechanisms are likely not going to get used with armorers carrying weapons in and out of weapon racks. An additional safety mechanism that is highly effective for high density weapon storage systems is the mechanical safety brake. This is a gravity fed mechanical safety brake along the bottom of the weapon racks at toe level in the carriage. Users need only apply pressure to the bar to cease closure should the carriages begin to collapse on an active aisle while they are still inside.

The mechanical safety brake is best used in active arms rooms with more than one access aisle and also for longer carriages. If an armorer forgets to press the push button on the handles to lock the carriages, the toe level bar (when pressed) automatically stops the carriage.

18″ Fire Sprinkler Clearance

Meeting fire and building codes is important to make sure your armory isn’t written up.

Fire code requires storage to be 18″ under sprinklers. When placing weapon racks on top of mobile carriages, we are adding 7″ of overall height to the weapon racks with the height of the track and 5″ wheels of carriages. This means we need to start with the floor to sprinkler height and deduct the growth of the carriages and the 18″ fire sprinkler clearance to know what height weapon rack we can use in your space.

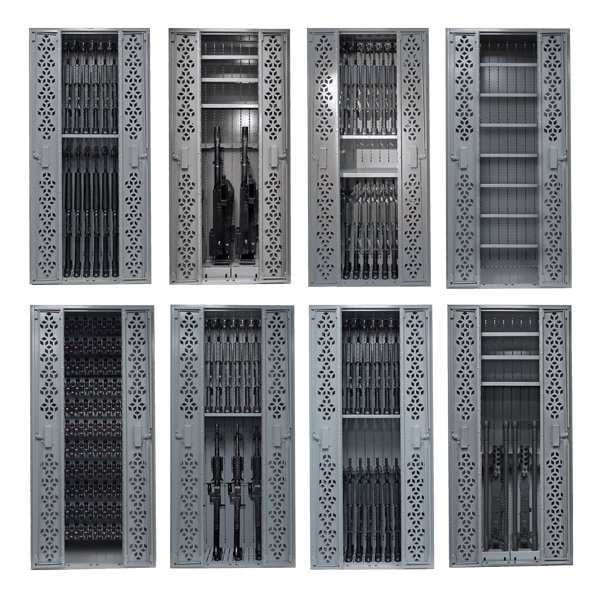

76″ H Combat Weapon Racks allow for some weapons to be stored double tiered depending on the height of each weapon.

- Double Tier carbines with room for storage shelves

- One tier of full height rifles (M16s/Shotguns) & one tier of carbines

85″ H Combat Weapon Racks allow for double tiering of rifles as well as mixing and matching of many different weapon systems and configurations.

- Double tier M16s & Shotguns

- Double tier M4s with M9s and multiple storage shelves

- Store M240s with M4s or shelves above

- Store M2/MK19s with M4s or shelves above

Combat Weapon Storage Systems have been designed in company arms rooms, portable

arms rooms, joint armories & special forces armories for all branches of military.